4

Inductive Sensors

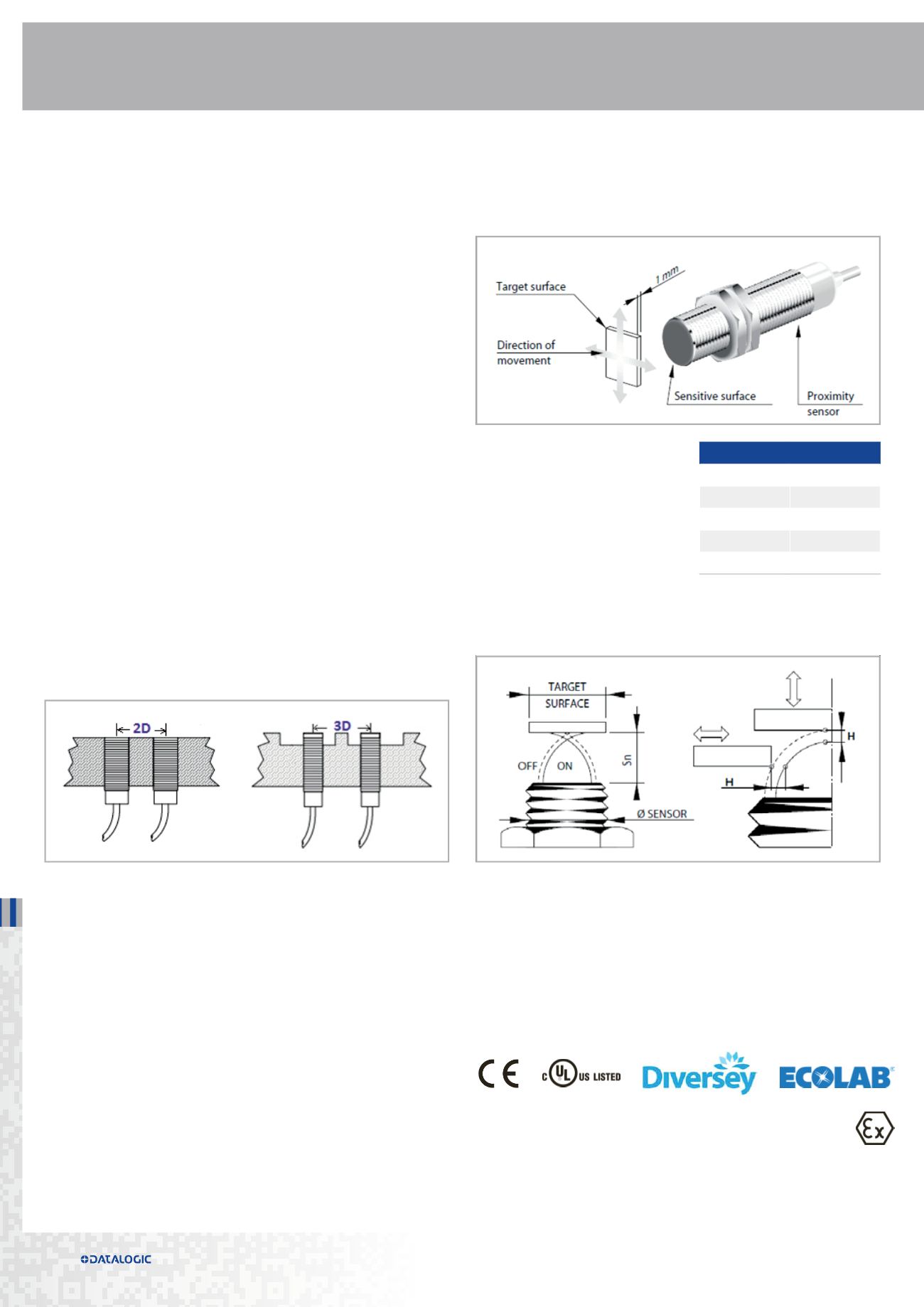

Inductive proximity sensors generate a magnetic field from their

detection faces. Whenever a detectable object moves into the sensor’s

field of detection, Eddy currents build up in the target and dampen the

sensor’s magnetic field. This effect triggers the sensor’s output. Since a

current in the target is needed for detection, inductive proximity sensors

are uniquely suited for detection of all types of metals.

ADVANTAGES

-Not affected by humidity and dust

-No moving parts, no mechanical wear

-Independent of the color of the object to detect

-No dead zone

DISADVANTAGES

-only detect metallic objects

-low operating distance

-sensitive to electromagnetic interference

(such as electric welding, induction ovens)

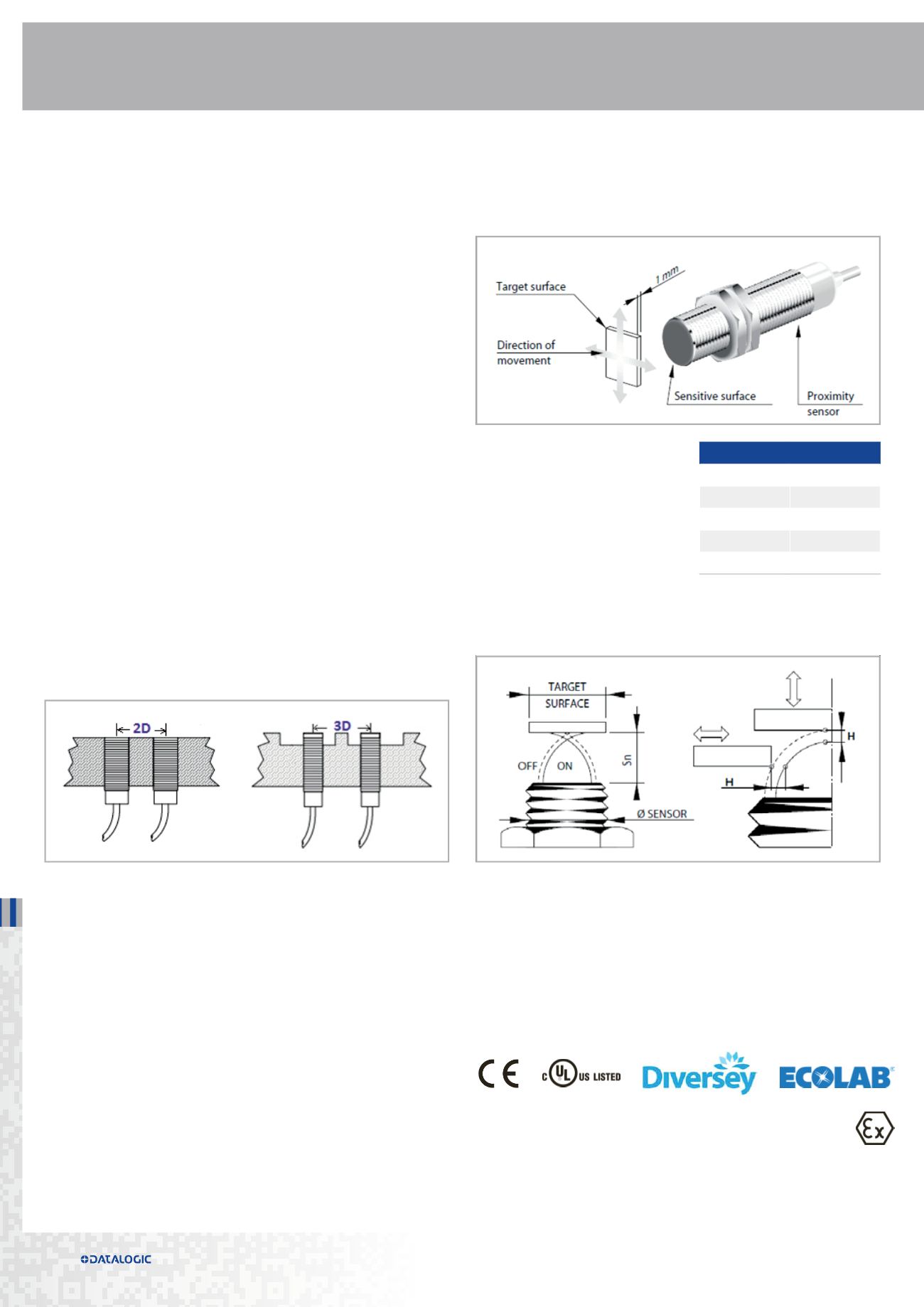

Shielded models - FLUSH mounting

Shielded models can be installed with their sensing faces flush to the

metal. The distance from opposing metal surfaces must be ≥ 3sn and

the distance between two proximity switches (side-byside) ≥ 2D.

Unshielded models - NON-FLUSH mounting

Unshielded models can be identified by their ‘caps”, since they have no

metal housing surrounding the area of the sensing face. The sensing

face must extend ≥ 2sn from the metallic installation medium. The

distance from opposing metal surfaces must be ≥ 3sn and the distance

between two adjacent proximity switches ≥ 3D. The metal body leaves

uncovered part of the sensing area resulting in an increased sensing

distance.

Main tubular models are available in both nickel plated brass and

stainless steel housing, with the active sensing face in LCP plastic.

METAL FACE version:

Are available stainless steel versions (M12,M18).

Are used in especially harsh environments and applications which

are too extreme for standard sensors. They resist to abrasive media,

aggressive cleaners and solvents with their rugged sensing face. IP67

protection.

WELD FIELD IMMUNE version:

These special field immune models are ideal for welding environments

and other applications where large magnetic fields are present. They are

rated for reliable operation near the current line carrying 20,000 amps.

NAMUR version:

Are available 2 wires versions (M5, M6,5, M8, M12, M18, M30). They can

be used in conjunction with suitable switching amplifiers, in explosive

systems or Zone 1 and Zone 2 areas.

The switch amplifier must be installed outside the explosive area.

Almost all versions have IP67 mechanical protection.

Nominal Switching distance (Sn) According to EN 60947-5-2

When an inductive proximity sensor is rated for sensing distance, it

refers to the sensor’s ability to detect the “standard detectable object”

at its specified sensing distance. The “standard detectable object” is a

1mm thick square piece of ferrous iron that is in height and width the

size of the proximity sensor’s detection face’s diameter.

Hysteresis (H):

distance between the point of switching on and the point of switching

off of the trigger object. The value is a percentage of the nominal

switching distance Sn.

AC/DC version:

Are available 2/3-wires versions (M12, M18, M30) , that operate in

alternating current with voltage drop of 5 V for currents of the order of

100mA.

To be able to provide a proper potential drop at the load, it is

recommended to power the sensors with at least a supply voltage equal

to the Voltage drop indicated (5V).

When the object to be detected is

a different metal material, multiply

the value of the rated operating

distance for a reduction factor.

The table beside shows the

reduction factors of the main

metals used in industry.

REDUCING FACTOR

Fe37

1 x Sn*

Stainless-steel

0,9 x Sn

Brass-Bronze

0,5 x Sn

Alluminium 0,4 x Sn

Copper

0,3 x Sn

M12/18/30 FLUSH models are ATEX certified

I I 3G EX nA II T6

I I 3D EX tD A22 IP67 T85°C

“M12/18/30 models are Diversey and ECOLAB tested”